Scheduling

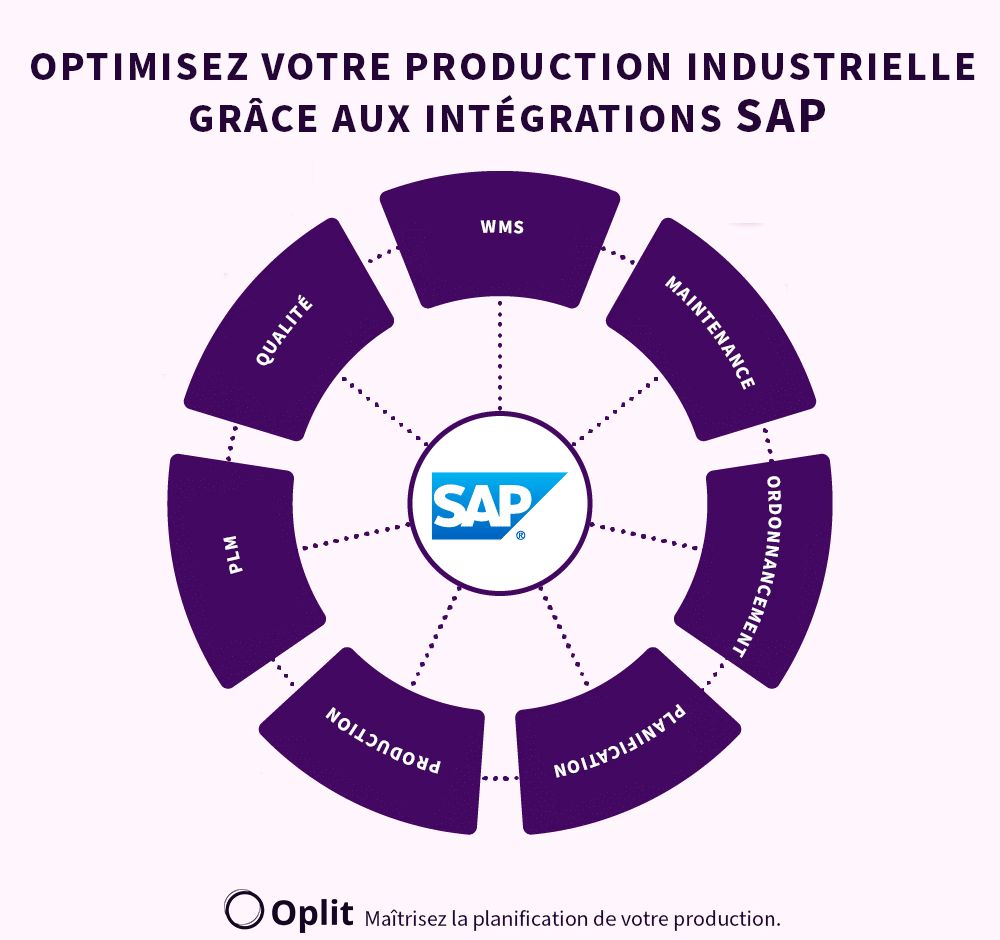

Best scheduling software integrated with SAP: Optimize your industrial production

06/02/2025

SAP dominates the ERP (Enterprise Resource Planning) market thanks to its robust architecture and efficient integration with industrial and financial processes. However, its planning module, while effective, has limitations when it comes to accurate production scheduling at the granular level. This article explores why and how scheduling software like Oplit can transform your production chain by enabling seamless communication between strategic planning and field execution.SAP is a major player in the ERP field, with a 21.6% market share in the global industrial sector according to a Gartner study (2022). Manufacturers value SAP for its ability to centralize data, harmonize processes, and establish connections between financial management and production operations.

SAP: A Powerful ERP but Limited for Scheduling

SAP is a comprehensive enterprise management solution, but its planning capabilities present certain constraints when it comes to efficiently scheduling production:

1. Suboptimal Ergonomics for Workshops

SAP PP/DS focuses on high-level planning (global resources, capacity management, etc.). However, it often lacks user-friendliness when transmitting precise instructions to operators on the shop floor.

2. Lack of Operational Granularity

SAP generally structures resource planning around work centers, which represent broad production units. However, this approach can be insufficient for workshop needs, where finer resource management is required.

In practice, knowing that an operation must be carried out in a specific work center is not enough. It is crucial to answer more detailed operational questions, such as:

On which specific machine should this operation be performed?

Some machines offer different performance levels depending on the type of product or required settings, directly impacting quality and production time.Which operator is the most qualified or available to perform this task?

In an industrial environment, managing operator skills and availability is essential for ensuring efficient scheduling and avoiding bottlenecks.

Without this level of granularity, production teams often need to manually adjust planning on the shop floor, leading to wasted time and a lack of visibility over real execution. An integrated scheduling solution with SAP helps address this limitation by dynamically assigning each task to the appropriate machine and operator, considering production constraints and unexpected events.

3. Difficulty in Running Simulations, Validating Objectives, and Tracking Execution

SAP excels in developing a master plan, allowing companies to structure their production at a strategic level. However, adapting this plan to real-world constraints presents challenges, especially in terms of simulation, goal validation, and execution tracking.

In a production environment, data is constantly evolving: supplier lead times fluctuate, machines break down, and operator availability changes. While SAP is effective at consolidating and structuring information, it struggles to react in real-time to these variations.

The main limitations include:

Limited Dynamic Simulation Capabilities

Generating alternative scenarios for testing different scheduling approaches is often cumbersome and rigid in SAP. Yet, the ability to simulate multiple options is critical for anticipating constraints and making informed decisions.Complex Validation of Production Objectives

SAP provides an overview of objectives but does not always facilitate their dynamic adjustment based on real workshop conditions, making it harder to quickly adapt to unforeseen changes.Limited Execution Tracking

Once the plan is deployed, SAP offers little granular visibility into real-time task progress. Often, companies must wait for end-of-day consolidations or manual feedback, delaying necessary adjustments.

In this context, an integrated scheduling tool helps bridge these gaps by ensuring real-time synchronization with operations. It enables manufacturers to quickly simulate different scenarios, adjust objectives based on production constraints, and precisely track each step of the process.

The Benefits of an Integrated Scheduling Tool with SAP

An integrated scheduling tool with SAP addresses these limitations by offering advanced functionalities. Here’s how it complements SAP to optimize your production:

1. Real-Time Communication via APIs

Modern scheduling tools like Oplit allow real-time synchronization with SAP through APIs. Instead of sending batch updates at fixed times, only modified data is transmitted between systems, ensuring instant updates.

2. Granular Scheduling

These tools refine scheduling down to individual operators and machines, allowing for better task assignment and detailed visibility into execution.

Advantages:

Optimized resource utilization

Reduced machine downtime

3. Improved Plan Adherence

The best scheduling tools provide real-time dashboards that compare task progress against the planned schedule, ensuring better alignment with production goals.

4. Intuitive Interface for Operational Teams

Unlike SAP’s often complex interface, scheduling tools provide user-friendly dashboards designed specifically for production managers and operators.

How to Choose the Best Scheduling Tool for SAP Integration?

1. Essential Features

A high-performance scheduling tool should include:

Advanced optimization algorithms to minimize resource conflicts.

SAP connectivity via standard APIs (RFC, IDocs).

Intuitive visualization of schedules through interactive Gantt charts or dedicated operator dashboards.

2. Best Available Options

Here’s an overview of commonly integrated scheduling software with SAP:

Software Strengths Limitations Oplit AI-driven, intuitive UX, granular workshop vision Less well-known than competitors Ortems Robust solution for advanced scheduling High cost Preactor Suitable for complex environments Long implementation time

Key Steps for a Successful SAP Integration

1. Process Analysis

Start by identifying your current gaps in SAP. Ask yourself:

What are the responsibility areas of each system, and where do they exchange information?

Are there delays in transmitting production plans to workshops?

Do your operators have the necessary information to execute tasks efficiently?

2. Implementing an Event-Driven API

An API allows seamless integration between SAP and the scheduling tool, eliminating the need for massive data transfers.

3. Team Training

To ensure successful integration, invest in training your teams on how to use the scheduling tool and its interaction with SAP.

4. Continuous Monitoring & Optimization

Once integration is complete, regularly analyze key performance indicators (KPIs) to identify areas for improvement.

Why Choose Oplit as Your SAP Scheduling Solution?

1. Simplified SAP Integration

Oplit leverages event-driven APIs for seamless synchronization with SAP, minimizing downtime and optimizing data management.

2. Advanced Features for Workshops

Unlike SAP, Oplit enables precise task assignment to individual operators or machines.

3. Proven Expertise

Many SAP-using companies have chosen Oplit to enhance their scheduling and execution tracking.

Conclusion

Integrating a scheduling tool with SAP is essential for any company looking to optimize its industrial processes. While SAP is a powerful planning solution, its limitations in granular scheduling and shop floor communication require a complementary approach. With tools like Oplit, you can transform your production chain by enhancing responsiveness, precision, and overall efficiency.

🚀 Looking to take your production to the next level? Explore how Oplit seamlessly integrates with SAP to boost your scheduling performance.